|

|

|

|

|

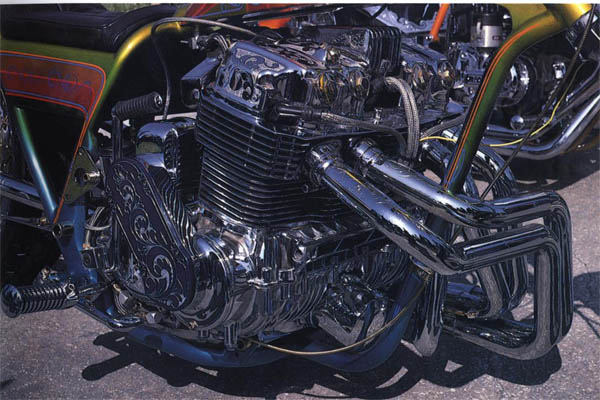

Another small, but effective detail is to counter sink the allen bolts on the covers .. that link will show some of them as does this one ... http://www.lowridersbysummers.com/bikes/sum4.jpg .. A couple thing to remember when countersinking ... 1) Its best to use a bottoming bit .. That's a bit that's made for this .. You end up with a hole with a flat bottom for the allen to set in .. You can use a normal drill bit.. but the allen bolt will only rest on the outer edge of the bottom of the hole becase the hole comes to a point with a regular twist drill bit.. The difference is .. the more surface of each bolt that holds the cover .. the better chance of a good seal.. (that make sence..??) 2) Do a few practice holes just to see how far you go in to have the allen head sit flush with the top of the cover .. Then try to make a stop for the bit .. or at least mark it so you can't go too deep .. That looks silly when the allen is below the surface and you might drill all the way through the cover as well.. 3) Be very careful of some of the outer edge holes.. That surface gets pretty thin and you don't want to break through ... 4) Notice that the allens

in the center Dyno cover don't look as deep as the others are. Thats because

I've taken away a lot of the surface material when I smoothed the cover.

If you aren't careful, you could drill through the remaing material in

that cover.

Heres some pics that will show various examples of this process.

c c

|

|

|

|

|

|

|

|

|

|

|

|